Ancien événement - 2018

03/10/2018 au 05/10/2018Adaptive Systemic Thinking Program

Adaptive Systemic Thinking

en 1ere mondiale en France

les 3, 4 et 5 octobre mai 2018

Instructor : Carol PTAK

Content :

The Adaptive Systemic Thinking Program™ conveys a proven repeatable process of systemic problem solving.It enables the executives of a compagny to innovate as described in the Demand Driven Adaptive Enterprise model (DDAE).

The Adaptive Systemic Thinking Program (ASTP)™

Driving Innovation and Adaptation

Today the very survival of an organization is subject to its ability to drive innovation and adaptation. Innovation and adaptation is driven by identifying and overcoming obstacles and risks to the system's ability to manage, grow and sustain flow, many of which often remain hidden under the surface and obscured from view.

Can Your Organization Think Systemically?

- Are people in your organization formally trained to think systemically?

- Do they have a common systemic language and framework to think and work within?

- Do people in your organization understand the connections between departments, resources and people?

- Are people given enough visibility to understand the connections between departments, resources and people?

- Are people discouraged from thinking and offering solutions outside of their area of responsibility?

- Do people understand how the different forms of variability affect the enterprise and FLOW through it?

How does your organization score with these questions?

If an organization's people can’t think systemically then that organization is blind to conflicts and distortions to relevant information at the systemic level. That means your organization is INCAPABLE of thinking and adapting for FLOW. Its ability to continue the progression through the Demand Driven Adaptive Enterprise (DDAE) Model will be compromised.

Install Thoughtware in Your Company

Through a blend of instructive formats participants learn a repeatable systemic problem-solving process, apply that process to a defined topic within their organization and learn and internalize the building blocks for sensing, adapting and innovating across the supply chain (customers and suppliers) for continual ROI improvement. The ASTP™ is intended for strategic level personnel and/or their direct reports. Examples include organizational, divisional and functional leaders, individuals responsible for implementing and guiding major initiatives, and internal consultants and/or corporate change agents. The seminar can delivered on an in-house basis to leadership teams. The program can be extremely effective with leadership teams looking to take and keep the company at the high stages of the DDAE Development Path.

About the Adaptive Systemic Thinking Program™

The Adaptive System Thinking Program™ was developed over a 20 year time span and has proven itself across a wide variety of environments. Based primarily on the thinking processes of the Theory of Constraints the ASTP™ is a streamlined but extremely effective vehicle to learn a process of strategic thinking that will leave an indelible mark on the way a person looks at problems and solutions within a system.

A cross functional team that goes through this program together grows together. They learn a new way of thinking, communicating and problem solving collectively. They better see connections across the company and begin to break down silo thinking and solution application.

About the Process

The Adaptive Systemic Thinking Program™ conveys a proven repeatable process of systemic problem solving.

1. Find a systemic problem. Learn how to make the connections across organizational symptoms that are potentially separated by function, location, etc and identify a systemic core problem that results in the persistence of those symptoms. Many organizations and managers fight the same fires on a frequent basis, waging the same tired battles over and over again. Intuitively, we know that as long as we continue to observe the same types of symptoms, we are not addressing the real underlying problem. But, how do we find the real problem? In an organization or functional area that continues to struggle with the same types of challenges or symptoms there are often underlying and unresolved dilemmas that tug people in at least two directions at once. These dilemmas often result in a constant and unsatisfactory set of compromises at all levels producing consistently poor or underwhelming results

2. Spark a breakthrough idea. Identify a specific idea that directly challenges the core problem. A breakthrough idea allows an organization or an individual to break the underlying dilemmas by attacking and invalidating the assumptions that hold them together. This yields a place to start in order to build a future state, one that does not include the current symptoms. It is a solution that is elegant; it is both simple and extremely significant. The simplicity comes from the fact that we are attacking the symptoms at fewer points (through the underlying dilemmas) and the significance is defined by the knowledge of how the symptoms are connected to and dependent upon the dilemmas.

3. Construct a full and immune solution. Construct a complete solution driving to the required results while ensuring there are no disastrous side-effects. A breakthrough idea is just a starting point. Other solution elements must be identified and incorporated to round out the solution and mitigate risks.

4. Plan to address obstacles. Develop an implementation path not based on arbitrary m ilestones but on the known and significant specific obstacles to be encountered in the environment with regard to the defined solution. This path should be carefully sequenced, identifying immediate primary objectives to achieve.

5. Implement and manage the change. Learn a tool set to use with people to facilitate and adapt your plan through implementation.

Instructor : Carol PTAK

Carol Ptak is currently a partner with the Demand Driven Institute and was previously a Visiting Professor and Distinguished Executive in Residence at Pacific Lutheran University. Before going to academia she was Vice President and Global Industry Executive for Manufacturing and Distribution Industries at PeopleSoft, where she developed the concept of demand driven manufacturing.

Ms. Ptak spent four years at IBM Corporation, culminating in the position of Global SMB Segment Executive.

A leading authority in the use of ERP and supply chain tools to drive improved bottom-line performance,

Ms. Ptak has an expertise that is well grounded in four decades of practical experienceas a successful practitioner, consultant, and educator in manufacturing operations.

Her pragmatic approach to complex issues and her dynamic presentation style make her a person in high demand worldwide on the subject of how to leverage these tools and achieve sustainable success.

Ms. Ptak holds an MBA from Rochester Institute of Technology and completed the EMPO program at Stanford University. She is a frequent educator at the university level and presentsat many key technical conferences around the world, including conferences in South Africa,France, Israel, Australia, Ireland, and the Netherlands and 11 APICS International Conferences.

She is the author of numerous articles and the books Orlicky’s Material Requirements Planning, third edition, with Chad Smith; MRP and Beyond; ERP: Tools, Techniques, and Applications for Integrating the Supply Chain; Theory H.O.W.: How Organizations Could Work with Harold Cavallaro; and Necessary but Not Sufficient with Eli Goldratt and Eli Schragenheim. Together with Dean Gilliam, she updated Quantum Leap, originally written by John Constanza.

Ms. Ptak has lent her name to the internationally coveted Ptak Prize for Supply Chain Excellence that is awarded annually by ISCEA, the International Supply Chain Education Alliance.

Ms. Ptak is certified through APICS at the fellow level (CFPIM) and was certified in Integrated Resource Management (CIRM) with the first group internationally.

Ms. Ptak was the President and CEO of APICS for the year 2000. Prior to her election as APICS President, she served at the Society in a variety of positions.

Plus d’information sur le site du Demand Driven Institute

Tarif : 3000 €HT Privilége adhérent-e Fapics : 2 800 €HT

Inscrivez-vous places très très limitées!

INSCRIPTION

évènements

Salon SITL 2025 - Paris

AfrSCM partenaire

Venez nous rencontrer dans la zone "Campus" pour échanger sur les bonnes pratiques en supply chain management.

Mercredi 02 avril 2025 à 17h00 - Paris

Assemblée Générale

Participer à l'Assemblée Générale 2025 qui se déroulera à Paris, lors du SITL ou en distanciel.

Vendredi 04 avril de 12h à 13h - Webinar

Certifications professionnelles en Supply Chain Management

Découvrez les certifications professionnelles promues par AfrSCM pour booster votre carrière.

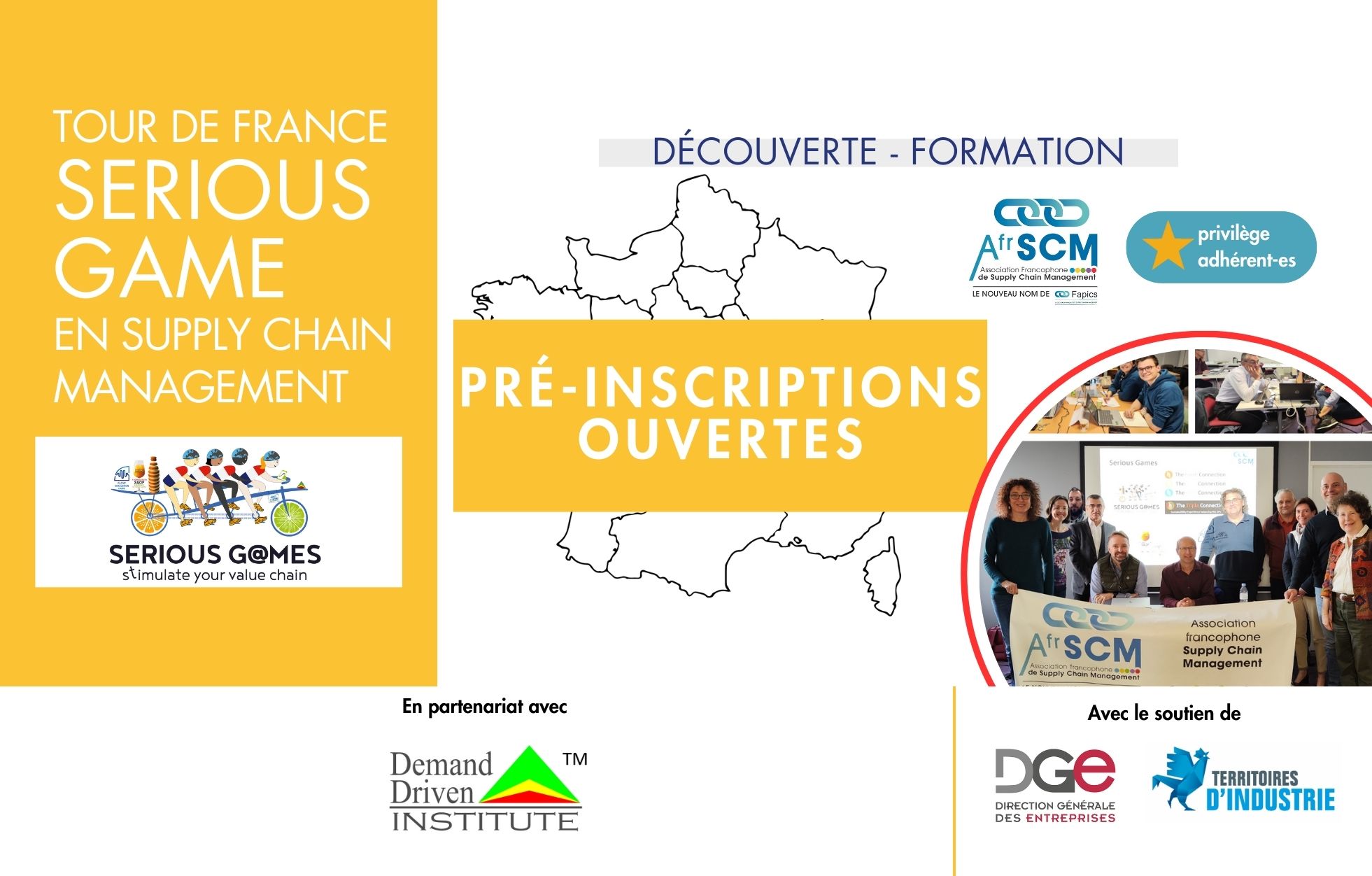

SERIOUS GAME PRE-INSCRIPTIONS

Tour de France Serious Game en Supply Chain Management

Pré-inscriptions ouvertes

Pré-inscrivez vous dans l'une des villes proposées et participez à une journée Fresh Connection Demand Driven (DDMRP)

NOS FORMATIONS CERTIFIANTES

1er semestre 2025 (date à définir)

Formation et certification Certified HealthCare Supply Chain Analyst

Obtenez une certification internationale avec le niveau de maîtrise nécessaire pour la bonne exécution des Supply Chain Sanitaires.

NOS FORMATIONS CERTIFIANTES

Lundi 05 et mardi 06 mai 2025

Formation et certification Certified Sustainable Supply Chain Professional

Obtenez une certification reconnue en pleine croissance à l’international en lien direct avec les problématiques de développement durable.